Production Tool Build

Sheet metal tooling using the following processes; progressive, transfer: automated and manual, along with assembly: components and fasteners.

-

ESTIMATING

ButtonOur experienced Estimators utilize Formingsuite software to help ensure accurate blank size for our quotes.

-

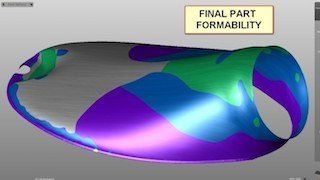

SIMULATION / DESIGN

ButtonUsing AutoForm forming simulation software, the Competition Engineering team develops and validates the production die process. All of our designs are made in Catia software and are in 3d solid model format.

-

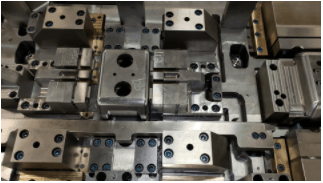

Machining

ButtonUtilizing MasterCam and Work NC software for CAM functions, we offer complete in-house CNC machining capabilities with our CNC machine centers, CNC lathes, wire edm machines, as well as our 5 axis laser.

-

ASSEMBLY

ButtonUtilizing years of tool and die making experience all tool details are inspected, finalized and assembled making them ready for tryout.

-

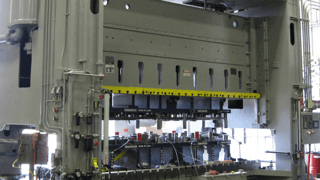

TRY-OUT

ButtonCompetition Engineering provides “production ready” tryout for all tooling. We are committed to manufacturing the highest quality tooling for our customers.

-

QUALITY

ButtonUtilizing CMM’s that use Metrologic software and a Romer Arm CMM with laser scanning to verify the accuracy and quality of each tool. Our goal is to manufacture precise tooling that meets and exceeds customer expectations.

Competition Engineering

All Rights Reserved

Competition Engineering