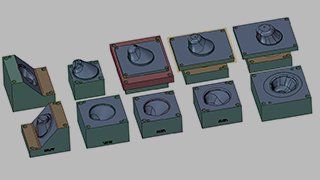

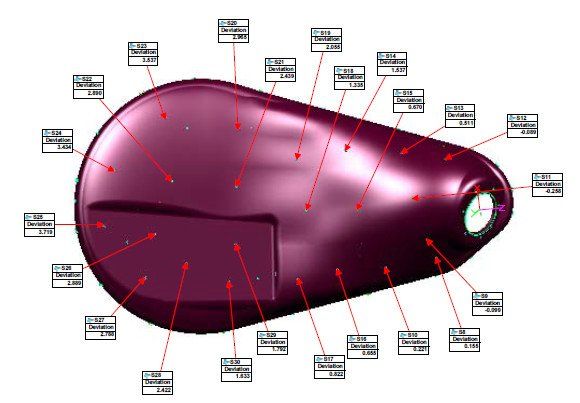

PROTOTYPES

Sheet metal prototypes – providing 1 to over 1000 pieces. Parts for testing, development, mock ups, early builds, production support, etc. We have a wide range of raw material in inventory for quick turnaround time. We are currently supporting domestic and international markets.